PE Coating Aluminum Composite Panel structure is essentially composed of three layers which together along with a coating of PE combine to form a highly insulated flat panel. The two layers of aluminum sheets are bonded together permanently with an internal core of polyethylene which when coated through PE makes the surface even more flat and highly resistant. An important point is that only the front of the panel is coated with PE (Polyester) Paint so that maximum damage can be absorbed without damaging the interior core and sheet.

Specifications

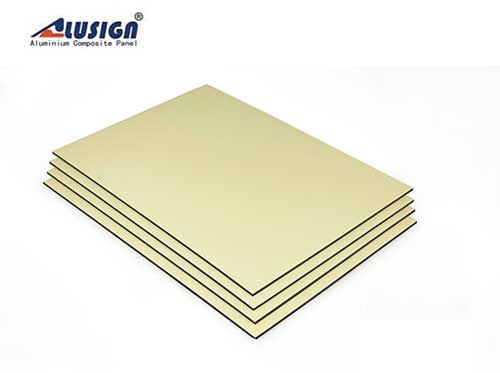

Aluminum skin thickness: 0.12mm-0.50mm

Total panel thickness: 2mm-6mm

Width:1000mm,1220mm(regular),1250mm,1300mm,1500mm,1550mm, 1575mm,2000mm(maximum)

Length: Up to 6500mm

Standard size: 1220mm(Width) ×2440mm(Length)

Warranty: We offer 20 years guarantee for PE Coating Aluminum Composite Panel

Surface Treatment: PE coating

Aluminum Source: South West Aluminum Factory

Painting Source: PPG&BECKER

Payment Term: TT, LC at sight, D/P, Western Union, Paypal

Note: Non-standard sizes and special colors are available depending on customers’ offers

Polyester Coating

Polyester when mixed with alkyd resins and ultraviolent absorbent makes the perfect surface that you can look for in a composite panel. PE coated panels are a great product which can be used in a variety of situations and their application itself is quite wide.

Features and Applications

PE coated panels have unique features which makes them the first choice when it comes to having a panel that is weather resistant. Qualities such as durability, strength, fire resistant, sound insulation, heat insulation and alkali resistant make it a standout product. One important thing that needs to be remembered is that the installation process of PE Coating Aluminum Composite Panel is fast and efficient which makes the entire process easier.

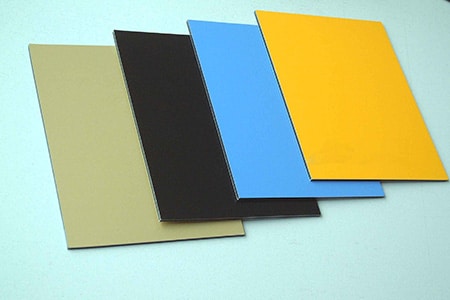

There is a reason why PE Coating Aluminum Composite Panel have been in high demand over the last few years, this is because of the fact that PE Coating Aluminum Composite Panel present quite versatile options with consistent features. The most common applications of PE coated panels would be the usage in interior decorations, billboards & signs, usage in partitions of rooms, low building claddings and ceilings. One of the biggest advantages of PE panels is the fact that they come out in a variety of colors for this sole reason the usage of PE Coating Aluminum Composite Panel in kitchens and rooms is also common.

We see that PE panels essentially follow the same purpose as compared to other flat panels but what needs to be remembered is that the coating of polyester gives it versatility in usage and applicability.

Available Colors and Size:

Sizes and special colors are available depending on customers’ offers, we can produce all colors on all professional color cards

Feature:

Weather resistance, high strength, easy maintenance/convenient for project construction/excellent processability/thermal resistance/sound insulation and good fire prevention performance/good plasticity, impact resistance/shock resistance/ good smoothness, light and strong/ to choose color/ gorgeous and colorful decorative, decorative pattern and design can be customized

About Alusign ACP Supplier

Production Capability: 600000SQM/Month

More Service: OEM, Samples free (samples will be sent in one day time)

Warranty: We offer 20 years guarantee for PVDF Coating Aluminum Composite Panel and 10 years guarantee for PE Coating Aluminum Composite Panel

Surface Treatment: PE coating

Payment Term: TT, LC at sight, D/P, Western Union, Paypal