What is Aluminum Composite Panel ?

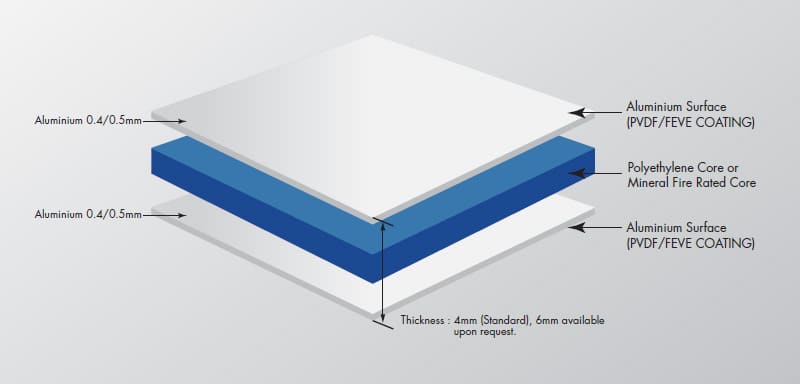

Many companies across the UK are unaware of the kind of Composite Insulated Panels they’ve in their premises. They remain unaware of the hazards that types could have on employees and their company. In most risk areas, insurance providers generally reject unapproved types of CIPs, and the cost of replacement to types that were authorized are essential to get most types of insurance cover, although significant. What panels? Composite panels have been used, from both internal and external building structure, as a result of their benefit of efficiency, over the past 25 years. A CIP includes 2 metal facings bonded to a central center, to form a sandwich.

The result is a strong insulated panel, which is installed to construct a structure with an improved efficiency. The advantages of such a panel include: Being simple to keep and clean – Top thermal insulation properties – Top power to weight ratio – Easy to manufacture – Quick and simple to install – These panels are usually found in warehouses, factories and internal sub branches, where varying room average temperature plays a major element. What’re the risks? The danger for panels rests with the type of insulation center. Commonly there are 6 major types of insulated center: Expanded Polystyrene – Extruded Polystyrene or Styrofoam – Polyurethane – Polyisocyanurate – Modified Phenolic Foam – Mineral Wool – These types can be divided between Loss Prevention Certification Board accepted cores and non approved cores.

Non Approved Cores – EPS and also XPS. The reason both polystyrene kinds are non authorized is because of their extremely combustible and burning properties. These kinds are known to produce molten droplets and also toxicity black smoke when exposed to fire and also extreme heat, which is then radiated throughout the core, and may ignite the metal skin, resulting in rapid destruction of the premises. This core has no fire resistance properties and also has a 95% likelihood that it’ll cause the fire to spread. PUR. As well has polystyrene, polyurethane will support combustion and also isn’t insurance authorized and very unsuitable for high threat areas.

Approved Cores – LPS 1181 or 1208 authorized PIR. This heart has enhanced fire performance compared to non-approved PUR and also PIR and also is acceptable in the majority of hazard applications, although still not in high threat applications like cooking premises. MPHEN. Phenolic Foam has improved fire resistance of up to sixty minutes and is accepted to LSP 1181. This core is appropriate for most hazard programs, however it’s less affordable than LBCP approved PIR.