What are the colors of aluminum composite panels?

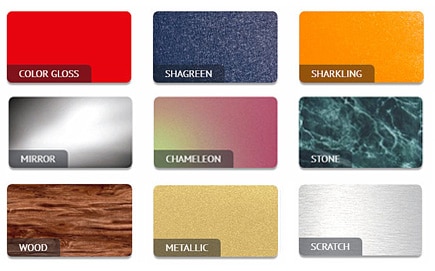

1. Different brands have different colors. There are about 30 kinds of conventional colors of aluminum composite panels, such as champagne silver, milky white, ivory white, jade silver, ingot gold, Chinese red, blue, mouse gray, black gold sand, etc. . The more common ones are mainly fluorescent colors, metallic colors, plain colors and pearlescent colors.

2. The color of the aluminum composite panel depends on the decorative object on the surface. The colors of different surface decoration effects are also different. For example, the coated decorative aluminum composite panel, the color of the decorative effect is metal Color, pearlescent color, fluorescent color, this kind of material is also a frequently seen one.

3. There are also oxidized colored aluminum composite panels. The colors of this decorative effect are rose red, bronze, etc., like film decorative composite panels. The colors of this effect are all texture types: grain, wood-grain board, etc. .

4. There are other special series of colors: the color of ordinary drawing is divided into silver drawing and gold drawing, the color of high-gloss aluminum composite panel is red and black, and the color of mirror aluminum composite panel is divided into silver mirror and gold mirror. There are also various types of wood grain and stone grain aluminum composite panels.

Second, the reasons for the chromatic aberration of aluminum composite panels

1. Process reasons. The difference in the production process of the product will inevitably cause the difference in the color of the product.

For the current domestic aluminum composite panel manufacturers, it is very difficult to achieve the same process control conditions, so there must be certain color differences between different batches or even between the same batch.

2. Reasons for raw materials. The supplier is different. The difference of suppliers has a great influence on the control of color production. Almost all the raw materials of the paint factory come from different places. If different suppliers are required to prepare the same color, in fact, there are already differences in the raw materials. Sometimes the same supplier also has the problem of differences in raw materials of different habit.

3. Equipment reasons. Different coating equipment also has certain differences in the strength and brightness of the coating. Different strength and brightness have a great impact on the visual perception of the human eye.